How Fluoron's Radiant Cleaning System helped Manitoba Kraft Paper

How Fluoron's Radiant Cleaning System helped Manitoba Kraft Paper

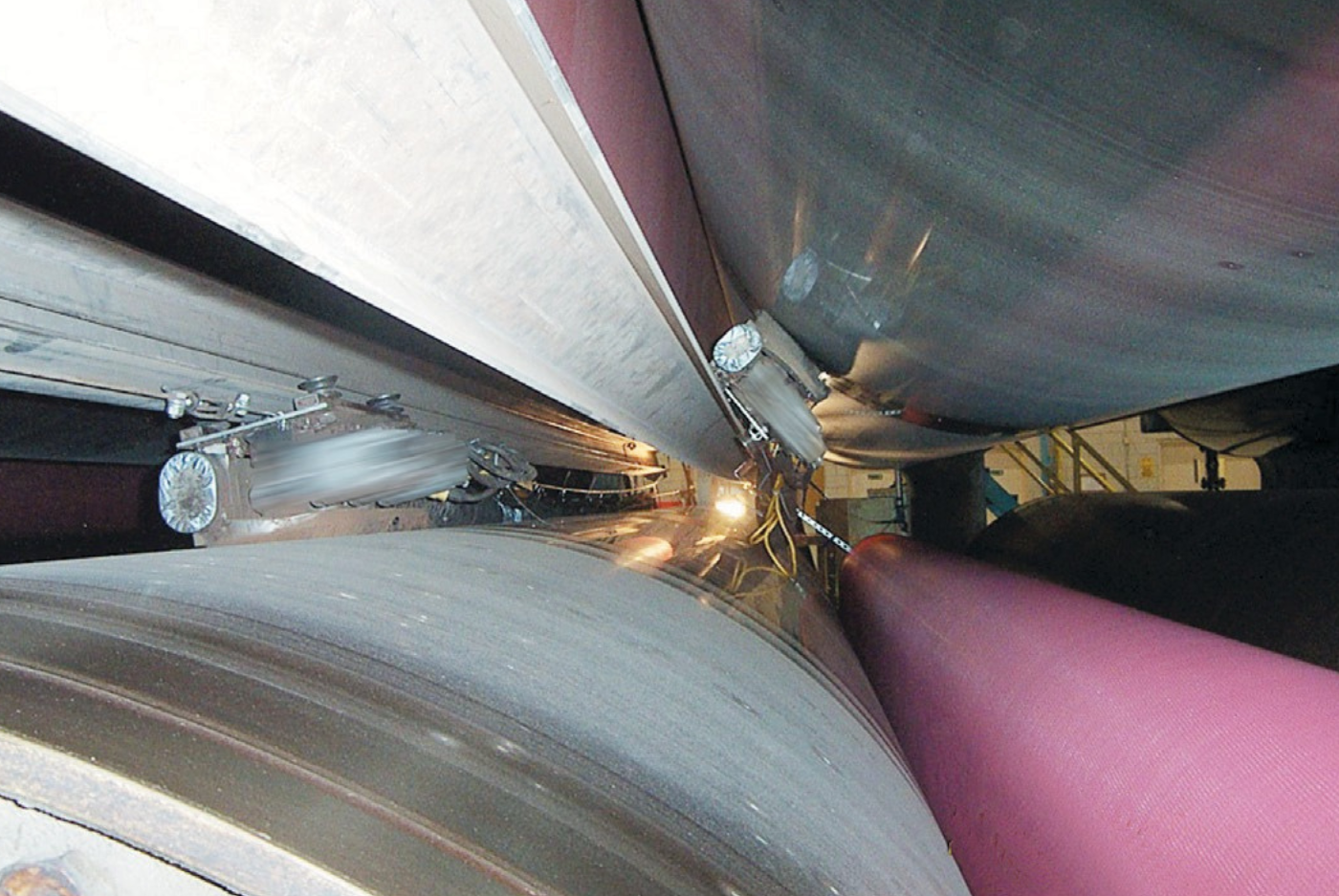

Juha Jarvinen of TOLKO Manitoba Kraft Papers was running at capacity and his machine was dryer limited. He needed to have his dryers cleaned to increase his machine speed and tonnage. He contracted with Fluoron Inc. to clean 16 dryer cans; 2 in the pre-dryer section, 8 in the first section, 2 in the second section and 4 in the third section. The benefits were even more than he had expected.

Mr. Jarvinen was happy to report the results to Rod Welen with Beckland (Fluoron’s Representative in Western Canada) “The dryer cans are performing very well since the cleaning job that the Fluoron guys did at Tolko Manitoba. We have gained approximately 1.5 metric tons/hr. in drying capacity at peak rates and this will also result in energy savings when running at lower rates due to improved heat transfer (unfortunately I do not have any quantification on energy savings yet). We are also experiencing a much “cleaner” sheet that is free of surface markings since the cleaning.”

“The Fluoron guys that were sent on site at Tolko were excellent and I think the workmanship was also excellent.” The increased production on the machine adds up to 36 metric ton per day. This could possibly add $6,000,000.00 in gross income.